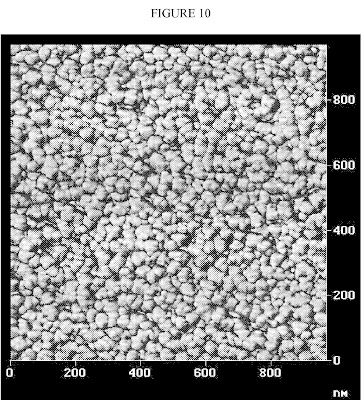

Uniaxial tensile tests showed that elastic modulus and yield stress of the blends were independent of particle size and network density of the rubber core. experiments were used to measure network densities in the rubber core of the various particles. This shows how epoxies can be toughened successfully for use in industrial and transport applications. The instantly recognizable shell toe is complemented by three serrated stripes and adidas Originals accents. The experiments were carried out with varying deformation rates and temperatures. Toughening using silica nanoparticles is especially efficient at low particle contents. Analytical models were used to predict the modulus and fracture energy the predictions agreed very well with the measured values. The fracture and toughening mechanisms were identified by scanning electron microscopy of the fracture surfaces. The fracture energy was measured at ambient and low temperature (− 40 ☌ and − 80 ☌) to understand the brittle fracture behaviour. An anhydride-cured thermosetting epoxy polymer has been modified by the addition of different wt% of silica nanoparticles, core–shell rubber particles and hybrids with equal wt% of both. Core-shell structured silicone rubber graft polymers, impact-resistant modified molding compounds and molded bodies and method for producing the sameCore-shell structured silicone rubber graft polymers, impact-resistant modified molding compounds and molded bodies and method for producing the same. Il modo migliore per ottenere ciò è di aggraffare gruppi reattivi nelle catene dello shell durante la produzione per polimerizzazione in emulsione, i quali poi reagiranno con la matrice polimerica ospitante.Įsiste però anche un effetto collaterale nell’uso di elastomeri: una diminuzione della rigidità superiore a quella che si ha con i modificanti d’impatto ***di natura core-shell**.The highly cross-linked thermosetting polymers used as adhesives and as the matrices of fibre composites for the construction of lightweight vehicles are very brittle, and finding effective toughening solutions for such engineering applications is a long-standing problem. L’accoppiamento può avvenire per interazione fisica tra il core dell’additivo e la matrice polimerica oppure per reazione chimica tra additivo e polimero. Core-Shell C18, 2.6 m COSMOCORE 2.6C18 Flow rate 0.8 ml/min 6SHFL❿DWLRQV 2.6C 18 2.6Cholester 2.6PBr Silica gel Core-shell type silica Average particle size P Core average diameter P Average pore size approx. Uno dei maggiori vantaggi di questi modificanti di impatto è che la dimensione delle particelle è predeterminata e mantenuta costante, tuttavia l’additivo deve essere ottimamente disperso ed ben accoppiato alla matrice polimerica per dare il miglior risultato. Questi additivi usualmente hanno un core di gomma a Tg molto bassa, come il polibutilacrilato o il polibutadione, ed una shell in PMMA (polimetilmetacrilato). In EN riscontro inoltre una maggiore frequenza di core shell rubber particles

In rete riscontro che core-shell viene spesso lasciato invariato A polymer comprising: a) a thermosetting epoxy-terminated oxazolidinone ring containing polymer modified by b) core shell rubber particles, wherein at least. Social Science, Sociology, Ethics, etc.Ĭore-shell rubbers Italian translation: gomme con struttura nucleo/guscio.A Core Concept, Activate a Planets Core, Dig deep, find the planet core, and figure out how turn it on. In this study, a CSR, pre-dispersed, diglycidyl epoxy of bisphenol A (DGEBA) mixture at 35 wt (KDAD-7101, Kukdo Chemical, Seoul, Korea. Print a Chemistry Lab Create Rubber or Plastic. ALBIDUR products consist of a reactive resin in which silicone elastomer particles of a defined size (0.1 3 m) are finely. By using core shell elastomers as tougheners, the viscosity increase becomes minimal. Core-shell rubber (CSR) nanoparticles are known to enhance the toughness of epoxy systems. One of the drawbacks of rubber toughening is the increase in viscosity, which cannot be tolerated in some injection methods. Extensive research, as presented in previous studies, 11 14 has been performed to study the addition of coreshell rubber (CSR) nanoparticles on the mechanical properties, thermal stability and fracture behaviour of epoxies and to establish the structureproperty relationship of rubberepoxy composites. General / Conversation / Greetings / Letters Automotive structural adhesives must show a steady toughness performance in the temperature range of 40 C to 80 C, considering their actual usage environments.

0 kommentar(er)

0 kommentar(er)